BaSys becomes 25

Innovations non-stop. In this way, our intention can be summed up in a double sense, with which we have been operating on the market for 25 years now. In a quarter of a century, we have developed a complete range of building hardware in Kalletal, Lippe, including hinge and striking plate systems for rebated and flush internal and external doors. We see ourselves as problem solvers for door and frame manufacturers throughout Europe as well as for national and international customers from trade and craft.

But it all began with furniture fittings, and this at the Oni Metallwarenfabrik in Herford, which belongs to the Hettich Group. It was here that the father of the two brothers who now run the business, Albert Bartel’s senior engineer for production rationalisation, took over the task of finding a new location for the growing furniture hinge business at the end of the 1950s. Bartels found this in the Kalletal, managed the move and the development of the business and was from then on responsible for the technical management.

From furniture fittings to building hardware

When Bartels meets Bernhard Herbers at the hardware fair in Cologne at the end of the 1960s, this paves the way from furniture to building hardware. Herbers, co-founder and then managing director of the door manufacturer Herholz in Ahaus, confronts Albert Bartels Senior with the idea of building fittings for automated door production. Soon the factory in Kalletal develops the first door hinges parallel to the furniture hinges. This brings other German industrial customers onto the scene. Albert Bartels Senior manages sales himself.

In the mid-1990s, the Hettich Group’s shareholder structure changes and with it its strategic orientation. The decision in favour of furniture fittings has far-reaching consequences for the plant in Kalletal, which at that time already produces 65 percent of door fittings. Albert Bartels Senior finally realises his plan and, together with his son Albert Bartels Junior, who had already trained as a toolmaker and then studied mechanical engineering, buys the company with 65 employees out of the Hettich Group. Thus, the name BaSys has stood for Bartels Systembeschläge since November 1995.

Fittings with system

Father and son first of all solve the investment backlog that had arisen due to the previous austerity measures and devote themselves to modernising the machinery and optimising the processes. In addition, they want to counteract the small-scale nature of the market and develop the building hardware – in accordance with the company’s self-imposed demand – according to a sophisticated system. The inherently consistent hinge and strike plate systems offer variability in load-bearing capacities and functions in milling-compatible groups. This reduces parts, facilitates processing and automation. BaSys is always closely involved with its customers during development, adapts its products to industrial production lines and keeps its ear close to the processor.

In 2001 Jürgen Bartels, Albert’s younger brother, also joins the family business, taking over the sales and marketing departments. During this time, BaSys is feeling the effects of the slump in the German door industry and begins to win customers abroad and build up its export business. This is accompanied by the constant commitment to a uniform European quality standard for concealed hinges as well as for certifications in order to comply with the respective country-specific building regulations, especially with regard to fire protection.

On the way to becoming an innovation leader

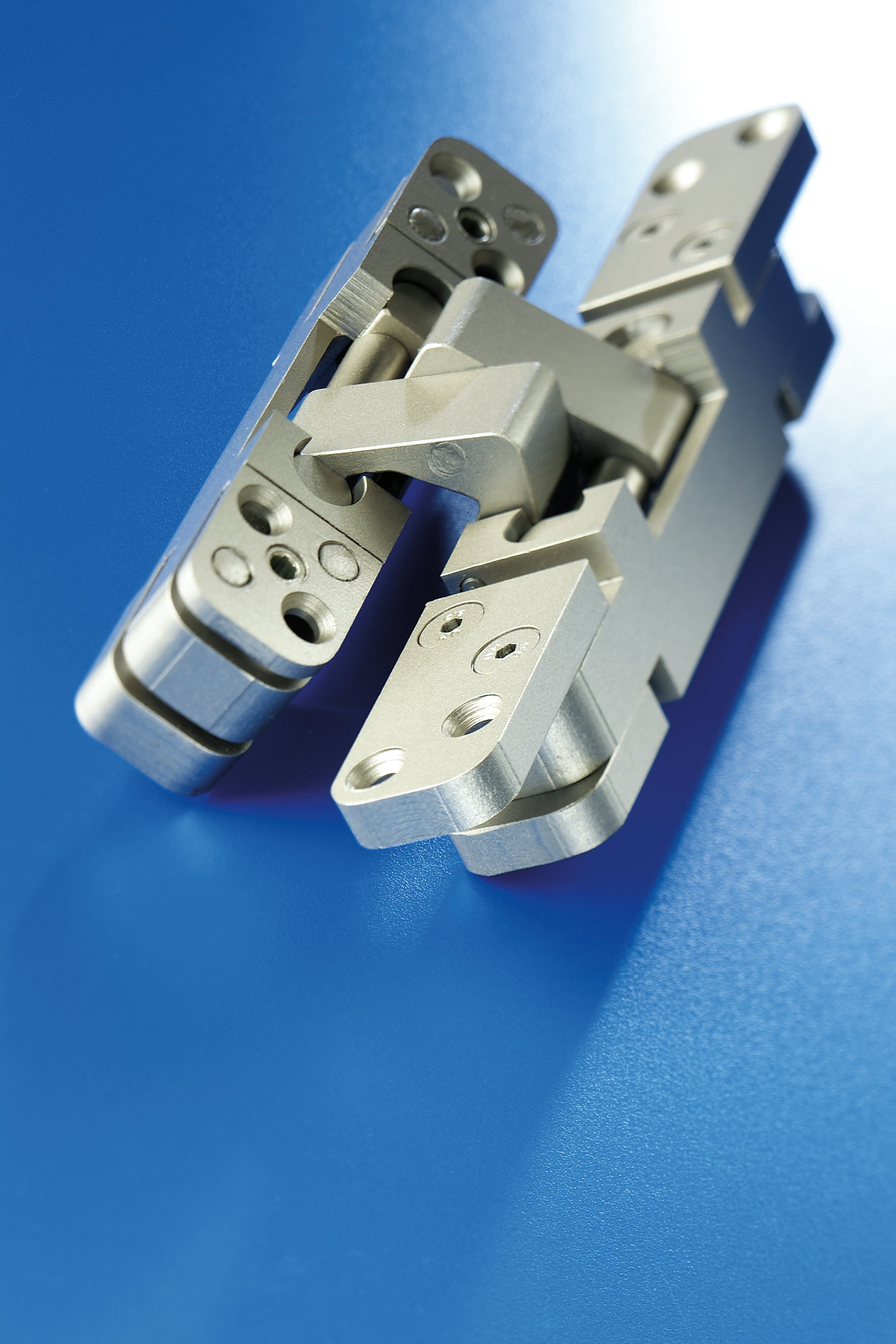

However, BaSys is still doing something to counteract the slump in sales at the beginning of the new millennium: At the BAU 2001 trade fair, the company is the first German manufacturer to present a concealed and three-dimensionally adjustable hinge for flush doors at the Herholz stand, thus initiating a new interior design trend.

The innovation becomes a blueprint for the future corporate strategy. The BAU and Fensterbau Frontale trade fairs set the pace at which BaSys presents its innovations. Twice a week, four application engineers in the company put their heads together and develop new product ideas and their integration into production processes in an open thinking process. Once a week, the two Bartels brothers are also involved, scrutinising technical implementation and marketing.

Numerous awards already testify to the innovative strength of the medium-sized company. These include, for example, the German Design Award 2016 for the “Master hinge FX2 120 3-D FD”, a concealed hinge for rebated house and flat doors with a large overlap and sash seal, whose pivot is located in the overlap for the first time. Just one year later, the concealed hinge “Pivota DX Close”, which gently and automatically pulls interior doors without visible door closers into the lock, receives the Innovation Prize Architecture + Construction and a “Best of best” in the Iconic Award: Innovative Interior 2018. BaSys 2018 celebrates its preliminary highlight with the TOP 100 award as one of the most innovative companies in German medium-sized businesses.

Individual solutions

The innovations are causing the order intake to rise steadily. BaSys is responding to this growth by expanding capacity at its Kalletal site. In 2012, the third hall will be built on the site in the Echternhagen industrial estate to make room for new investments. In 2017 BaSys builds hall 4 and relocates the automatic punching shop. This will be accompanied by further investments, for example in new surface technology. A high vertical range of manufacture and lean, fast production processes ensure flexibility, with which BaSys can meet individual customer requirements and deliver smaller batch sizes.

Stable in the crisis

25 years after the company was founded, we consider ourselves well positioned. In 2019, around 100 employees worked in two shifts on 5,000 square metres to create added value. In 2020, we expect to reach the previous year’s level. During the Corona crisis, BaSys has so far not had to resort to short-time working and has been able to offer its employees secure jobs.

With German-speaking customers in the D/A/CH region and in South Tyrol, we have so far come through the crisis relatively stable. The foreign-language foreign market, in which BaSys operates primarily through contract business, is showing signs of growth. With an export share of 30 percent, we now deliver to 36 countries worldwide, primarily within Europe, but also to North America and the Near and Middle East.

Down-to-earth and familiar into the future

Albert Bartels Senior retired from the management in 2012. Since then the brothers Albert and Jürgen Bartels have been managing the company together in the second generation with a clear division of responsibilities. As a technician, Albert is responsible for production and associated processes, Jürgen is in charge of marketing and sales. Both attribute the low staff turnover to their down-to-earth Lippe mentality, which also ensures that BaSys, as one of the largest employers in the region, does not have to worry about the next generation of skilled workers. And the next generation in the owner family is also getting ready to take over the company.

So in November 2020, all signs point to the future. Instead of celebrating the pandemic, BaSys is looking ahead to BAU, which is now taking place digitally, and is dedicating its innovative strength entirely to the new products for 2021. In September, we already proved that we can present these new products in an informative, entertaining and entertaining way at our own “Digital Expo”. After all, we claim to be open and curious about new and unknown things – just as you would expect from an innovative company.